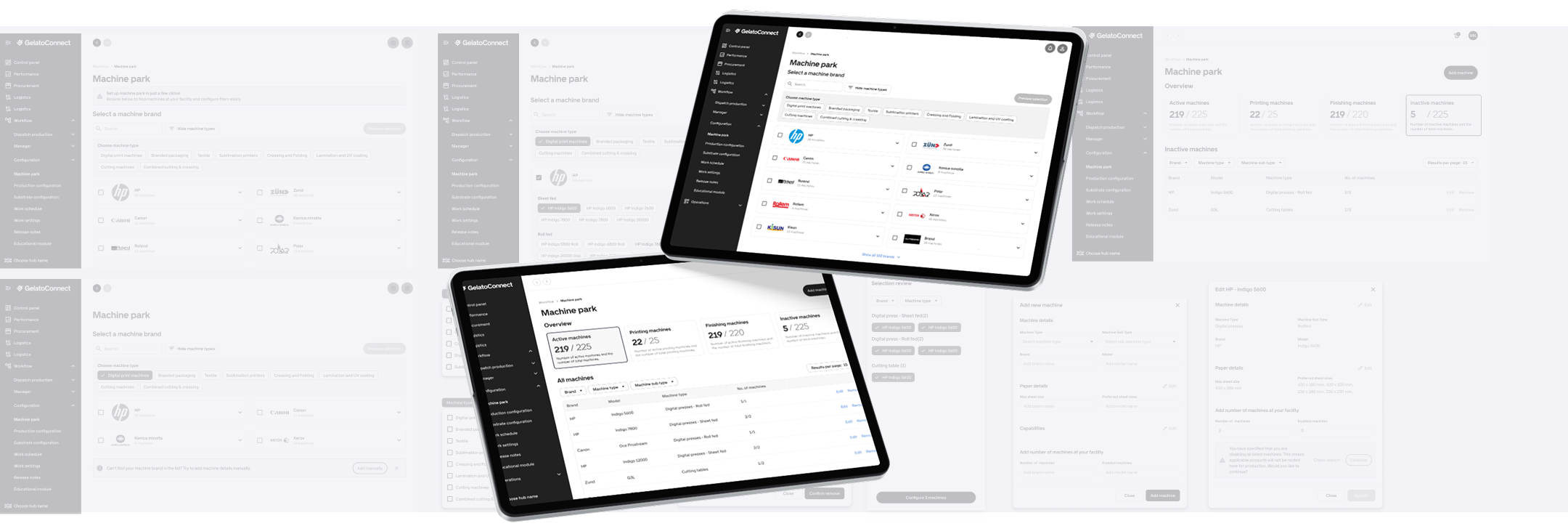

Machine park case study – Enhancing efficiency through user-centred design

Optimising onboarding with self-serve solutions and simplified machine status updates

The machine park is a comprehensive inventory system for tracking and managing all equipment in a product house, though not all machines were initially mapped. To streamline this process and reduce the need for on-site visits, we developed an innovative solution that empowers partners to independently identify and add machines to the system through an intuitive, user-friendly interface and workflow.

My role

I was responsible for enhancing the onboarding process to make it more efficient and user-friendly. My role involved:

- Conducting a thorough analysis of the existing process to understand its challenges and impact.

- Identifying gaps from both the user and Gelato’s perspective to pinpoint areas for improvement.

- Developing a solution that would optimise outcomes for both users and Gelato.

The results were significant:

We successfully created a self-serve onboarding platform with an intuitive UI, which greatly simplified the process.

- Onboarding time was reduced by 70%, significantly improving efficiency.

- The platform had a real-time impact on business operations, enabling the routing of jobs based on machine availability.

- This solution empowered partners to independently manage machine inventory, streamlining operations and enhancing overall productivity.

Project background

Gelato’s success hinges on maintaining a seamless workflow that allows customers to order customised products online and have them produced with high quality at global production houses. A critical factor in this process is accurately tracking the capacity and status of machinery across production partners.

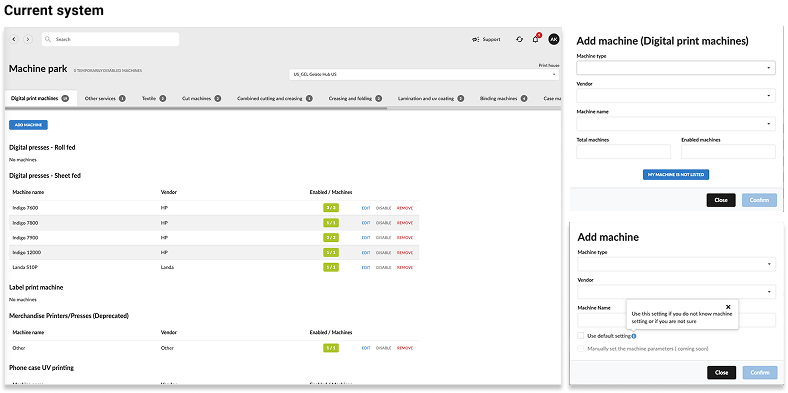

However, the current system for managing machine status and onboarding is inefficient:

- Onboarding new production partners is cumbersome, requiring Gelato representatives to travel on-site for manual setup.

- The machine catalog is incomplete, with some equipment categorised vaguely as “Other” without proper details.

- Updating machine status, such as marking a machine as non-operational, relies on a convoluted email-based process.

These inefficiencies have led to operational issues, including potential misallocation of jobs to unavailable machines. To optimise production capacity and ensure uninterrupted service, Gelato needs a more streamlined, real-time solution for machine management and status updates

The challenge

Gelato faced a significant challenge in maintaining a seamless workflow due to inefficient machine status updates and onboarding processes, which relied heavily on manual interventions and outdated communication methods. This resulted in operational inefficiencies, including incomplete machine catalogs and delayed updates, which could lead to misallocated jobs and compromised customer satisfaction.

This issue was particularly critical during peak months (November to January) when millions of orders needed to be processed. During these high-volume periods, any machine-related issues became extremely time-sensitive. The reliance on email communication for machine status updates often led to delays and errors, resulting in financial losses and potential damage to Gelato’s reputation.

Solution

To address these challenges, we developed a comprehensive, user-centric solution:

- Self-serve onboarding platform: We created an intuitive interface that allows production partners to independently onboard and catalog their machines, eliminating the need for on-site visits by Gelato representatives.

- Real-time machine status updates: The new system enables production partners to update machine statuses instantly, ensuring that Gelato’s job routing system always has the most current information.

- Expanded machine catalog: We improved the machine categorisation system, allowing for more detailed and accurate representation of each production house’s capabilities.

- Streamlined communication: By integrating machine management directly into the partner portal, we eliminated the need for email-based status updates, reducing delays and potential miscommunications.

- User-friendly interface: The entire system was designed with ease of use in mind, ensuring that partners can quickly adapt to and efficiently use the new tools.

This solution streamlines the onboarding process and significantly improves operational efficiency, particularly during peak seasons. By empowering partners with self-serve tools and ensuring real-time updates, Gelato can maintain a more accurate view of its production capacity, leading to better job allocation and improved customer satisfaction.

Building on the challenges identified earlier, we focused on streamlining the onboarding process for new production partners and improving machine management. After conducting over 10+ user interviews with production houses and collaborating closely with our customer success team, we identified key pain points and priorities.

The most critical issue that emerged was the need for quick and accurate machine identification and status tracking. To address this, we developed two main workflows:

Onboarding: We created a streamlined process for new partners to easily catalog and add their machines to the Gelato system.

Overview: We designed an intuitive dashboard for partners to monitor active and inactive machines, including reasons for inactivity and projected reactivation dates.

These solutions aimed to significantly reduce onboarding delays, improve operational visibility, and enhance overall efficiency for both production partners and Gelato

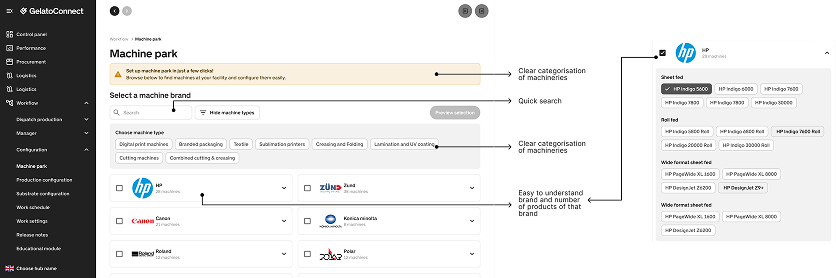

Onboarding

The new onboarding screens offer several key advantages:

Simplified integration: For production partners, the new self-serve onboarding platform allows them to seamlessly integrate into the Gelato Network with minimal effort. This eliminates the need for Gelato representatives to travel on-site for manual setup.

Efficiency: The streamlined process allows partners to quickly catalog and add their machines to the Gelato system. The new system also enables production partners to update machine statuses instantly, ensuring that Gelato’s job routing system always has the most current information.

Accuracy: The improved machine categorisation system allows for more detailed and accurate representation of each production house’s capabilities.

Improved communication: By integrating machine management directly into the partner portal, the new screens eliminate the need for email-based status updates, reducing delays and potential miscommunications.

Enhanced user experience: The entire system was designed with ease of use in mind, ensuring that partners can quickly adapt to and efficiently use the new tools. This frictionless interaction minimises errors and ensures consistency across all channel

Cost saving and scalability comes as the bi-product of this system.

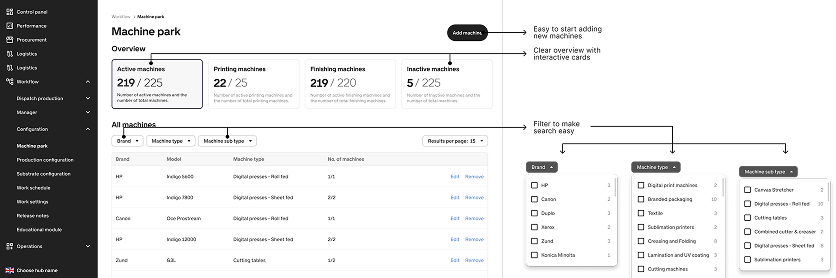

Overview

The overview screen serves as a central hub for production partners to monitor and manage their machine inventory efficiently. Key features and benefits of the overview screen include:

Real-time status dashboard: Partners can quickly view the status of all their machines at a glance, distinguishing between active and inactive equipment.

Detailed machine information: Each machine entry displays essential details such as type, brand, and model, making it easy to identify specific equipment.

Inactivity insights: For inactive machines, the screen provides reasons for downtime and projected reactivation dates, enabling better planning and communication.

Quick actions: Partners can easily update machine statuses, add new equipment, or modify existing entries directly from the overview screen.

Filtering and sorting: Advanced filtering options allow partners to quickly find specific machines or groups of equipment based on various criteria.

Capacity visualisation: The screen offers a visual representation of the production house’s current capacity, helping partners make informed decisions about accepting new jobs.

Historical data: Partners can access historical performance data for each machine, aiding in maintenance planning and productivity analysis.

Integration with job routing: The overview screen directly feeds into Gelato’s job routing system, ensuring that only available machines are considered for new orders.

This comprehensive overview screen empowers production partners with the information and tools they need to manage their equipment effectively, ultimately contributing to smoother operations and improved service delivery within the Gelato network.